What is the Fangjinlong?

Established in 2010 and honored every day since. Qingdao Fangjilong ‘s mission is providing unparalleled quality and service in every aspect of our operations, As a chemical expert and supplier, the company has invested 2 chemical plants and it relies on the research and development of technology of the Environmental Science and Engineering of Ocean university of China . The main products are including water treatment chemicals ,Mining chemicals,industrial chemicals and some special use chemicals . Fangjinlong undertakes and provides support for market-driven research,strives for commercialization of the technologies to benefit the industry and the society at large, as well as to promote the economic growth and sustainability of the earth. begin your partnership with Fangjinlong , please contact us here.

Wastewater Treatment Process

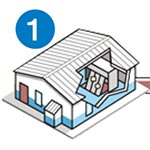

Stage One — Bar Screening

Removal of large items from the influent to prevent damage to the facility’s pumps, valves and other equipment.

Removal of large items from the influent to prevent damage to the facility’s pumps, valves and other equipment.

The process of treating and reclaiming water from wastewater (any water that has been used in homes, such as flushing toilets, washing dishes, or bathing, and some water from industrial use and storm sewers) starts with the expectation that after it is treated it will be clean enough to reenter the environment.

The physical process of wastewater treatment begins with screening out large items that have found their way into the sewer system, and if not removed, can damage pumps and impede water flow. A bar screen is usually used to remove large items from the influent and ultimately taken to a landfill.

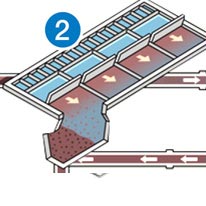

Stage Two — Grit Removal

Removal of grit by flowing the influent over/through a grit chamber.

Removal of grit by flowing the influent over/through a grit chamber.

Fine grit that finds its way into the influent needs to be removed to prevent the damage of pumps and equipment downstream (or impact water flow). Too small to be screened out, this grit needs to be removed from the grit chamber. There are several types of grit chambers (horizontal, aerated or vortex) which control the flow of water, allowing the heavier grit to fall to the bottom of the chamber; the water and organic material continue to flow to the next stage in the process. The grit is physically removed from the bottom of the chamber and discarded.

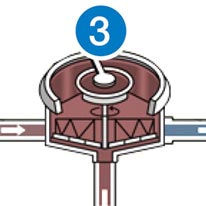

Stage Three — Primary Clarifier

Solids known as organics/sludge sink to the bottom of the tank and are pumped to a sludge digestor or sludge processing area, dried and hauled away. Proper settling rates are a key indicator for how well the clarifier is operating. Adjusting flow rate into the clarifier can help the operator adjust the settling rates and efficiency.

Solids known as organics/sludge sink to the bottom of the tank and are pumped to a sludge digestor or sludge processing area, dried and hauled away. Proper settling rates are a key indicator for how well the clarifier is operating. Adjusting flow rate into the clarifier can help the operator adjust the settling rates and efficiency.

After grit removal, the influent enters large primary clarifiers that separate out between 25% and 50% of the solids in the influent. These large clarifiers (75 feet in diameter, 7½ inches at the edges and 10½ feet in the center as an example) allow for the heavy solids to sink to the bottom and the cleaner influent to flow. The effectiveness of the primary clarification is a matter of appropriate water flow. If the water flow is too fast, the solids don’t have time to sink to the bottom resulting in negative impact on water quality downstream. If the water flow is too slow, it impacts the process up stream.

The solids that fall to the bottom of the clarifier are know as sludge and pumped out regularly to ensure it doesn’t impact the process of separation. The sludge is then discarded after any water is removed and commonly used as fertilizer.

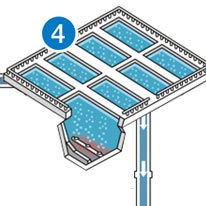

Stage Four — Aeration

Air is pumped into the aeration tank/basin to encourage conversion of NH3 to NO3 and provide oxygen for bacteria to continue to propagate and grow.

Air is pumped into the aeration tank/basin to encourage conversion of NH3 to NO3 and provide oxygen for bacteria to continue to propagate and grow.

Once converted to NO3, the bacteria remove/strip oxygen molecules from the nitrate molecules and the nitrogen (N) is given off as N2↑ (nitrogen gas).

At the heart of the wastewater treatment process is the encouragement and acceleration of the natural process of bacteria, breaking down organic material. This begins in the aeration tank. The primary function of the aeration tank is to pump oxygen into the tank to encourage the breakdown of any organic material (and the growth of the bacteria), as well as ensure there is enough time for the organic material to be broken down. Aeration can be accomplished with pumping and defusing air into the tank or through aggressive agitation that adds air to the water. This process is managed to offer the best conditions for bacterial growth. Oxygen gas [O2] levels below 2 ppm will kill off the bacteria, reducing efficiency of the plant. Dissolved oxygen monitoring at this stage of the plant is critical. Ammonia and nitrate measurements are common to measure how efficient the bacteria are in converting NH3 to N2↑.

A key parameter to measure in wastewater treatment is Biochemical Oxygen Demand (BOD). BOD is a surrogate indicator for the amount of organic material present and is used to determine the effectiveness of organic material breakdown. There are a number of other tests used to ensure optimal organic material breakdown (and BOD reduction) such as measuring pH, temperature, Dissolved Oxygen (DO), Total Suspended Solids (TSS), Hydraulic Retention Time (flow rate), Solids Retention Time (amount of time the bacteria is in the aeration chamber) and Mixed Liquor Suspended Solids. Ongoing and accurate monitoring is crucial to ensure the final required effluent BOD.

Stage Five — Secondary Clarifier

Treated wastewater is pumped into a secondary clarifier to allow any remaining organic sediment to settle out of treated water flow.

Treated wastewater is pumped into a secondary clarifier to allow any remaining organic sediment to settle out of treated water flow.

As the influent exits the aeration process, it flows into a secondary clarifier where, like the primary clarifier, any very small solids (or fines) sink to the bottom of the tank. These small solids are called activated sludge and consist mostly of active bacteria. Part of this activated sludge is returned to the aeration tank to increase the bacterial concentration, help in propagation, and accelerate the breakdown of organic material. The excess is discarded.

The water that flows from the secondary clarifier has substantially reduced organic material and should be approaching expected effluent specifications.

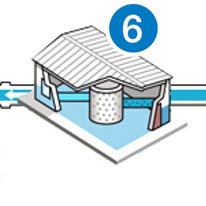

Stage Six — Chlorination (Disinfection)

Chlorine is added to kill any remaining bacteria in the contact chamber.

With the enhanced concentration of bacteria as part of the aeration stage, there is a need to test the outgoing effluent for bacteria presence or absence and to disinfect the water. This ensures that higher than specified concentrations of bacteria are not released into the environment. Chlorination is the most common and inexpensive type of disinfection but ozone and UV disinfection are also increasing in popularity. If chorine is used, it is important to test for free-chlorine levels to ensure they are acceptable levels before being released into the environment.

With the enhanced concentration of bacteria as part of the aeration stage, there is a need to test the outgoing effluent for bacteria presence or absence and to disinfect the water. This ensures that higher than specified concentrations of bacteria are not released into the environment. Chlorination is the most common and inexpensive type of disinfection but ozone and UV disinfection are also increasing in popularity. If chorine is used, it is important to test for free-chlorine levels to ensure they are acceptable levels before being released into the environment.

Stage Seven — Water Analysis & Testing

Testing for proper pH level, ammonia, nitrates, phosphates, dissolved oxygen, and residual chlorine levels to conform to the plant’s NPDES permit are critical to the plant’s performance.

Although testing is continuous throughout the wastewater treatment process to ensure optimal water flow, clarification and aeration, final testing is done to make sure the effluent leaving the plant meets permit specifications. Plants that don`t meet permit discharge levels are subject to fines and possible incarceration of the operator in charge.

Although testing is continuous throughout the wastewater treatment process to ensure optimal water flow, clarification and aeration, final testing is done to make sure the effluent leaving the plant meets permit specifications. Plants that don`t meet permit discharge levels are subject to fines and possible incarceration of the operator in charge.

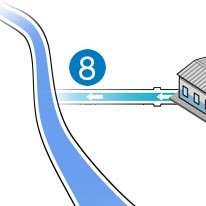

Stage Eight — Effluent Disposal

Final effluent flows into rivers or streams or into irrigation reservoirs for reuse.

After meeting all permit specifications, clean water is reintroduced into the environment.

After meeting all permit specifications, clean water is reintroduced into the environment.

Wastewater treatment and disposal

The size and capacity of wastewater treatment systems are determined by the estimated volume of sewage generated from residences, businesses, and industries connected to sewer systems as well as the anticipated inflows and infiltration (I&I). The selection of specific on-lot, clustered, or centralized treatment plant configurations depends upon factors such as the number of customers being served, the geographical scenario, site constraints, sewer connections, average and peak flows, influent wastewater characteristics, regulatory effluent limits, technological feasibility, energy consumption, and the operations and maintenance costs involved.

The predominant method of wastewater disposal in large cities and towns is discharge into a body of surface water. Suburban and rural areas rely more on subsurface disposal. In either case, wastewater must be purified or treated to some degree in order to protect both public health and water quality. Suspended particulates and biodegradable organics must be removed to varying extents. Pathogenic bacteria must be destroyed. It may also be necessary to remove nitrates and phosphates (plant nutrients) and to neutralize or remove industrial wastes and toxic chemicals.